OSHA Defines a Trench As Understanding Trench Safety and RegulationsTrenching is a common part of construction and utility work, but it also ranks among the most dangerous activities in the industry. Every year, trench collapses lead to serious injuries and fatalities. To reduce these risks, the Occupational Safety and Health Administration (OSHA) has set strict definitions and safety standards for trenching operations.

This topic explains what OSHA defines as a trench, the safety hazards involved, and the regulations that protect workers in trenching environments.

What Is a Trench According to OSHA?

OSHA defines a trench as a narrow excavation made below the surface of the ground. Specifically, the depth of the excavation is greater than its width, and the width at the bottom is not greater than 15 feet.

This definition distinguishes a trench from a general excavation, which may be wider and not necessarily narrow in design.

Why OSHA’s Definition Matters

The definition is more than just a technicality. It determines the type of safety regulations that apply to a specific excavation. Because trenches are often deep and narrow, they are more prone to cave-ins, making them a high-risk environment. Recognizing the difference helps employers apply the correct safety procedures and protective systems.

Common Uses of Trenches

Trenches are frequently used in

-

Laying utility lines (water, gas, electricity)

-

Installing drainage systems

-

Sewer and pipeline projects

-

Foundation footings

Though these projects vary in scope, all involve the risk of trench collapse, especially when soils are unstable or protective systems are absent.

The Main Hazards of Trenching

Trenching hazards can be life-threatening and often occur suddenly. The primary risks include

-

Cave-ins The most serious hazard, often fatal.

-

Falling objects Tools, materials, or debris can fall into the trench.

-

Hazardous atmospheres Gases or lack of oxygen in the trench.

-

Water accumulation Unexpected flooding or seepage weakens trench walls.

-

Falls Workers falling into unguarded trenches.

-

Utility line contact Accidental hits to gas or electrical lines.

Understanding these risks is essential for creating a safe trenching worksite.

OSHA Trenching and Excavation Standards

To address these hazards, OSHA enforces specific trenching and excavation standards found in 29 CFR 1926 Subpart P. Some key requirements include

-

Protective systems must be used for trenches deeper than 5 feet unless the excavation is made entirely in stable rock.

-

A competent person must inspect trenches daily and as conditions change.

-

Access and egress must be provided in trenches deeper than 4 feet, such as ladders or ramps.

-

Trenches must be kept free of water accumulation unless managed properly.

-

Materials and equipment must be kept at least 2 feet from trench edges.

These rules are designed to prevent incidents and protect workers’ lives.

Who Is a Competent Person?

OSHA defines a competent person as someone who is

-

Capable of identifying hazards related to trenching

-

Authorized to take corrective actions

-

Knowledgeable in soil analysis and protective systems

A competent person must inspect trench conditions at least once per day, and more often if weather or site changes affect safety. Their role is vital in maintaining ongoing compliance and safety.

Types of Protective Systems

Protective systems are required to prevent trench walls from collapsing. OSHA outlines several types

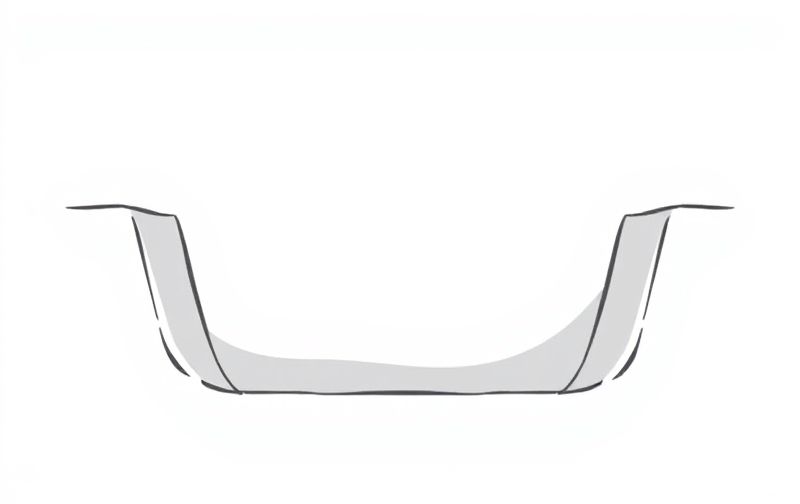

1. Sloping

This method involves cutting back the trench wall at an angle away from the excavation. The angle depends on the soil type and depth.

2. Shoring

Shoring uses hydraulic supports, timber, or other materials to hold up the trench walls.

3. Shielding

Also known as trench boxes, shielding systems protect workers within the trench even if a collapse occurs.

Each system has its pros and cons, and the choice depends on soil conditions, depth, and type of work being done.

Soil Classification and Its Role

Soil type directly affects the stability of a trench. OSHA classifies soils into

-

Type A Most stable, such as clay

-

Type B Medium stability, like silt or angular gravel

-

Type C Least stable, including sand or water-saturated soil

Understanding soil composition helps determine the safest approach to trench design and support.

Safe Work Practices in Trenches

To minimize risk, workers and employers should follow these basic trench safety practices

-

Always wear personal protective equipment (PPE).

-

Do not enter an unprotected trench.

-

Stay clear of heavy machinery near trench edges.

-

Use proper access points like ladders spaced every 25 feet.

-

Monitor for changes in trench conditions, including vibrations or soil cracks.

-

Train all crew members on trench safety awareness.

These habits promote a safety-first culture and reduce preventable accidents.

Emergency Preparedness

Despite precautions, emergencies can still happen. Employers should have a clear emergency response plan that includes

-

Immediate evacuation procedures

-

Communication systems

-

First aid access

-

Contact information for emergency services

Workers should be trained in what to do during a trench collapse or other incident. Quick and coordinated action can make a critical difference.

Enforcement and Penalties

OSHA actively enforces trenching standards. Violations can lead to

-

Financial penalties

-

Project shutdowns

-

Criminal charges in the case of fatal negligence

In recent years, OSHA has launched national emphasis programs focused on reducing trenching fatalities. Compliance is not only a legal obligation it’s a moral one.

Real-Life Examples and Lessons

Tragic stories of trench collapses underscore the need for strict adherence to safety practices. Workers have lost their lives simply because basic rules were ignored trenches left unshored, uninspected, or improperly designed.

These incidents are avoidable with proper planning, training, and supervision.

OSHA defines a trench as an excavation that is deeper than it is wide, not exceeding 15 feet in width. This definition shapes how safety rules are applied in construction and utility work. With the right planning and protection, trenching can be done safely.

Employers must take OSHA’s trench safety standards seriously, ensuring that all trenches are properly supported, inspected, and managed. Lives depend on it.

By understanding the regulations, training workers, and using proper protective systems, workplaces can prevent accidents and maintain a safe environment for everyone involved.